BASIC CROSSBARS

BASIC CROSSBARS

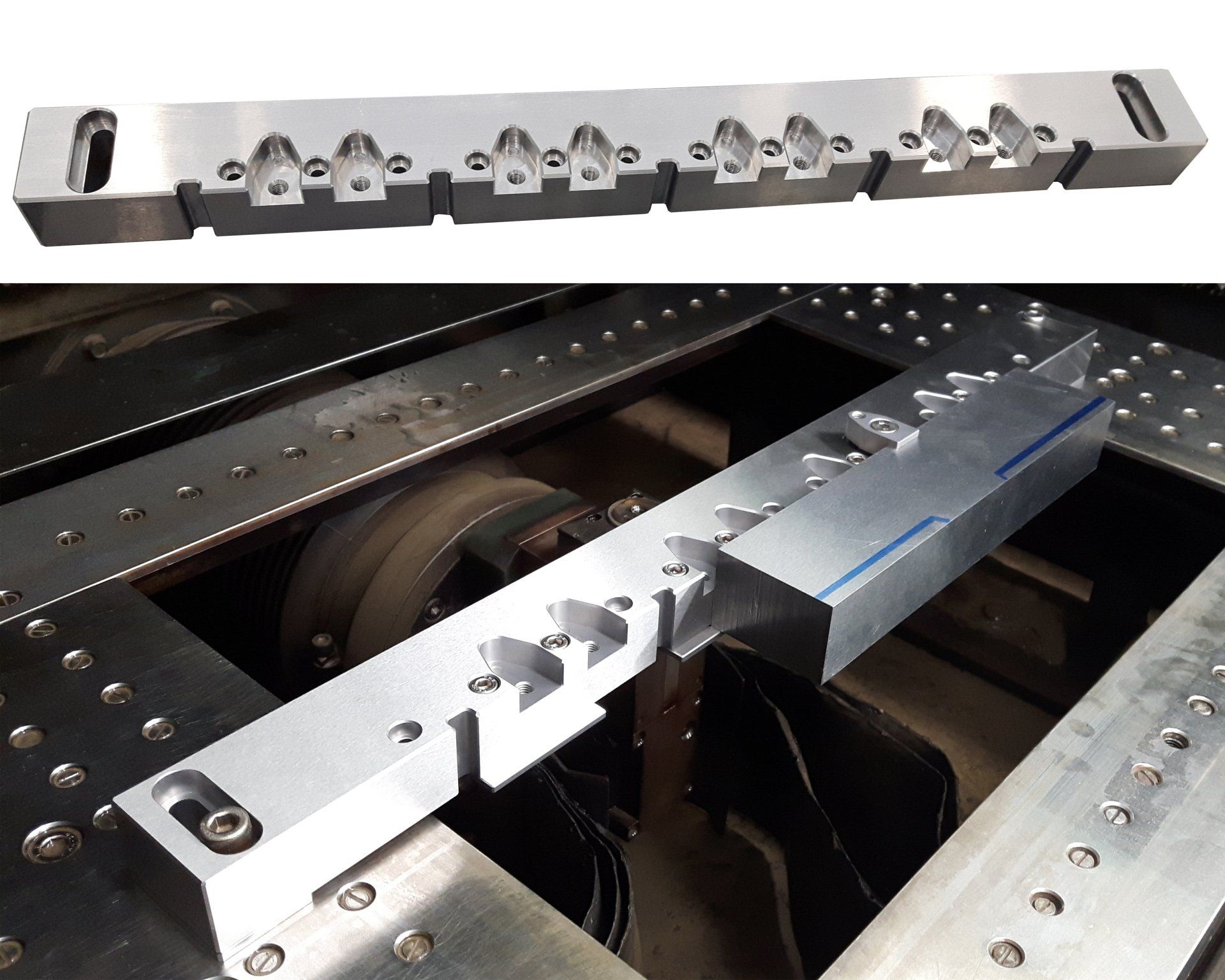

These are monobloc crossbars with fixing slot made according to the distance between holes of each machine table.

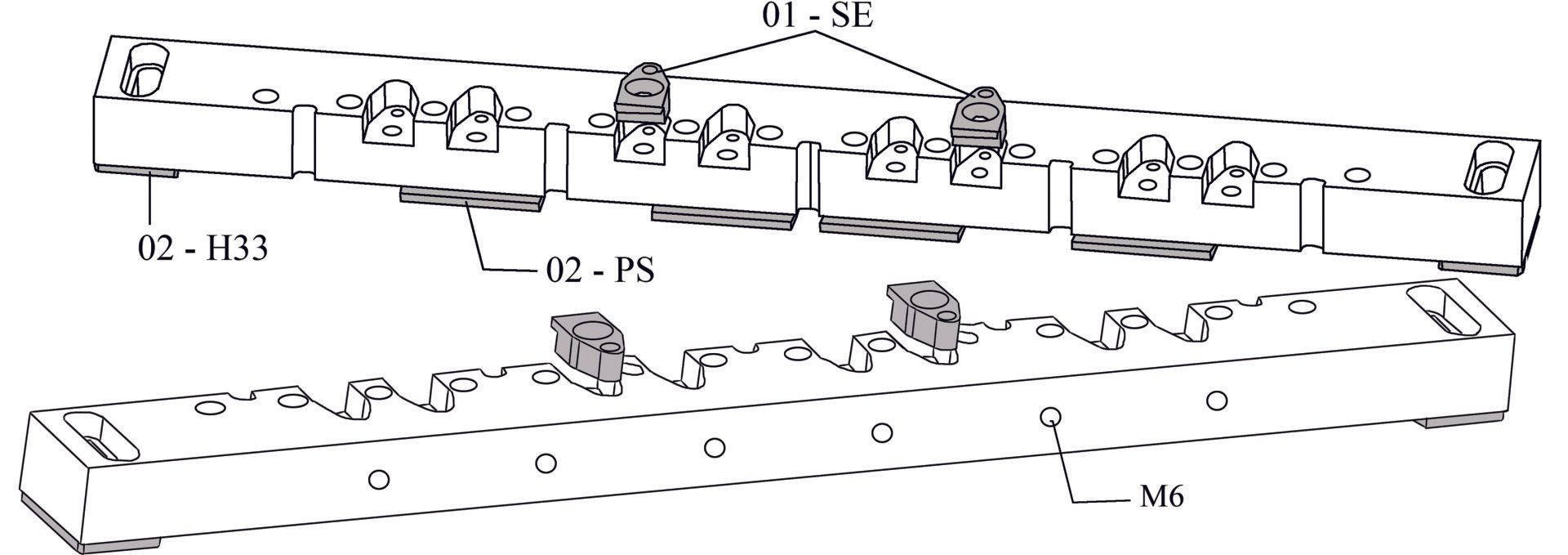

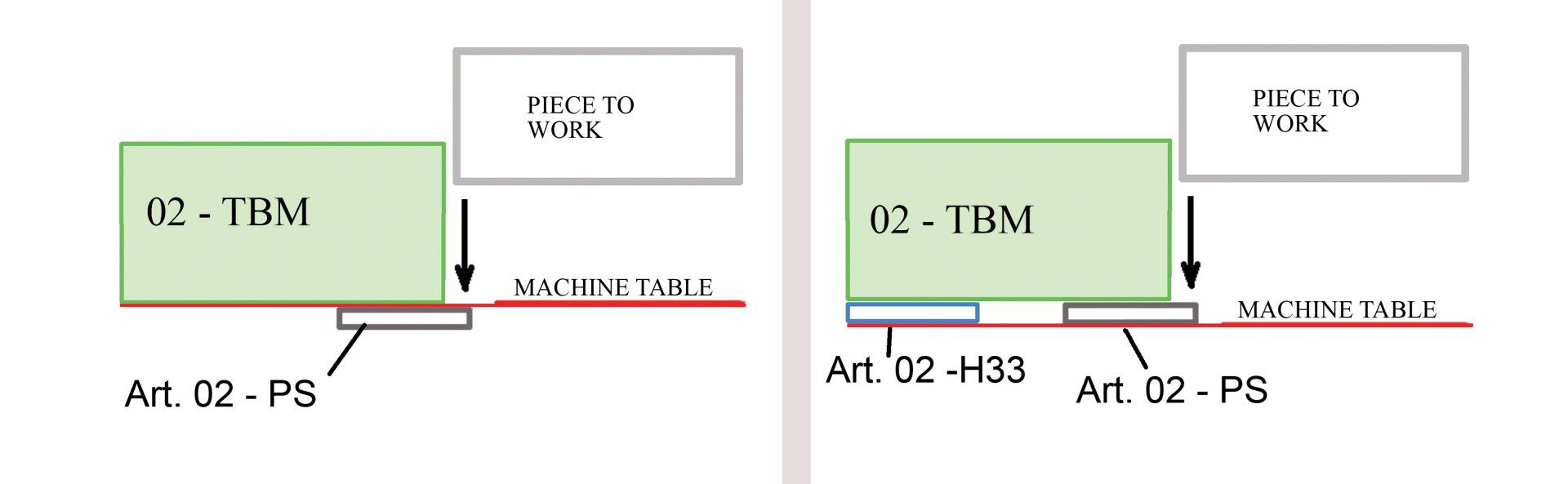

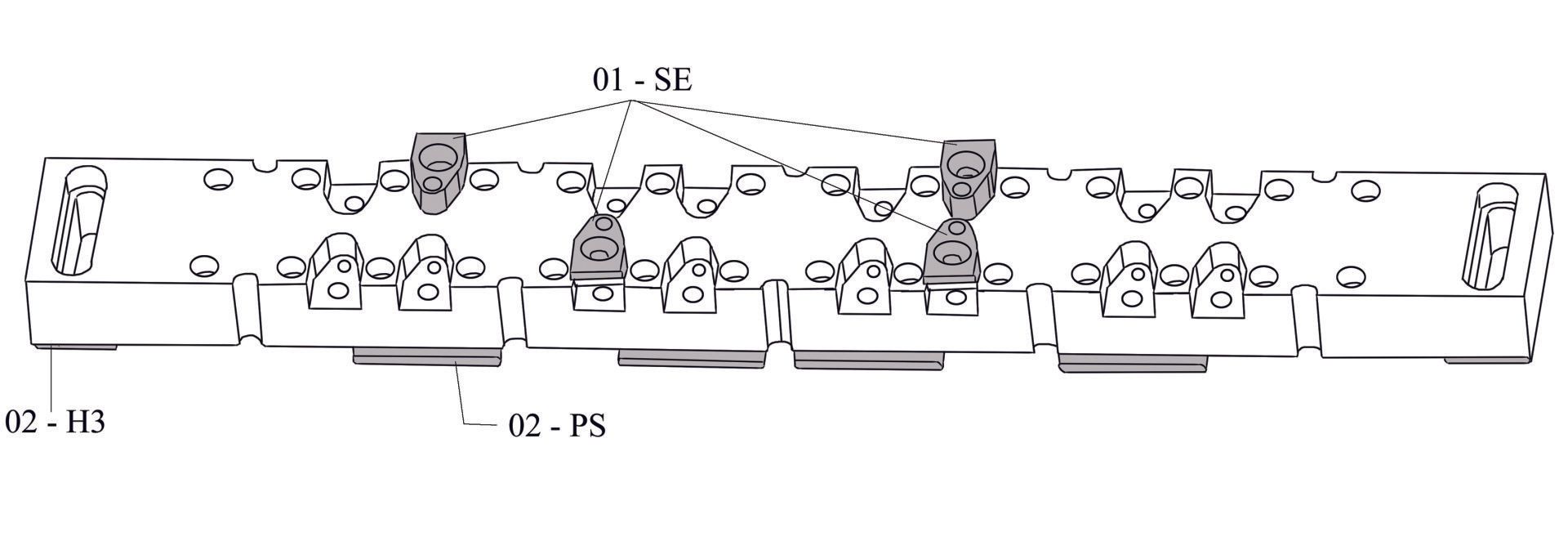

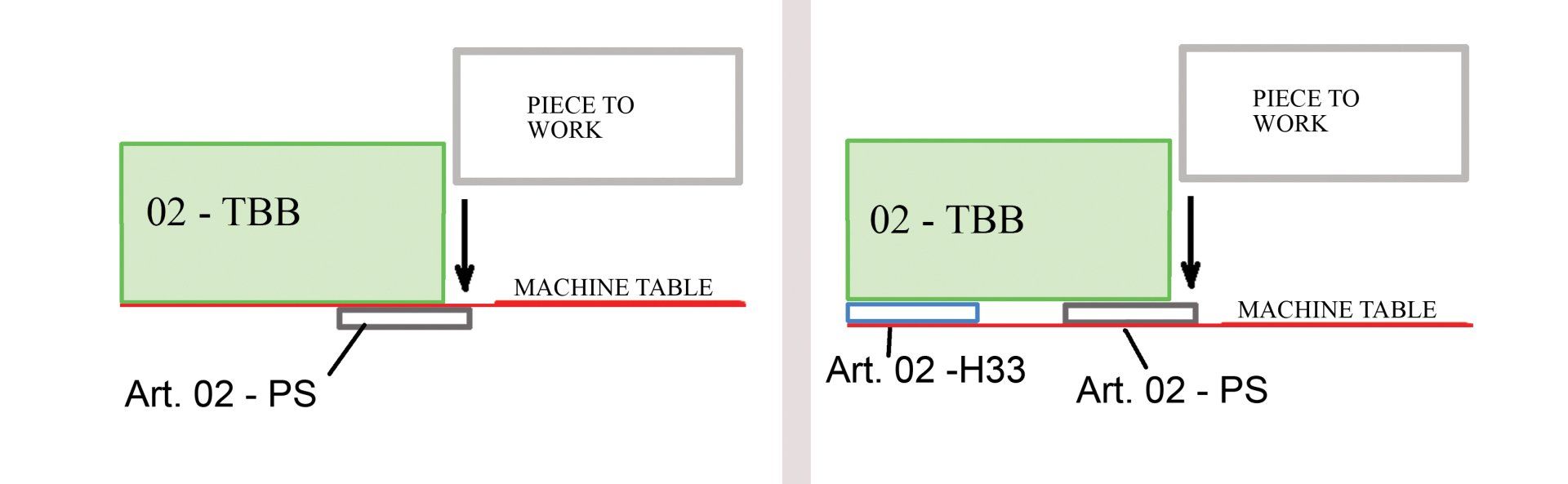

Each crossbar is equipped with fixing brackets Art. 01 - SE, and with a series of workpiece holders plates Art. 02 - PS and two anti-collision spacers Art. 02 - H33 which, by using them, allow the free passage of the lower wire guide head, and the positioning of the workpiece at 3. 3 mm with respect to the machine table. If the spacers 02 - H33 are removed, the workpieces to be machined will be at zero with respect to the machine table.

02 - TBM

BASIC CROSSBAR MONOLATERAL

From CHF 1.681,00

Crossbars with 25 mm span adjustment.

In the opposite bank to the one of the workpiece holder plates there are holes with M6 thread that allow the fixing of pieces with particular geometries.

The piece is fixed using the brackets 01 - SE.

For work with the work piece

placed at the same height as the machine table

For work with the work piece

placed at 3.3 mm from the table of the machine insert the spacer 02 - H33

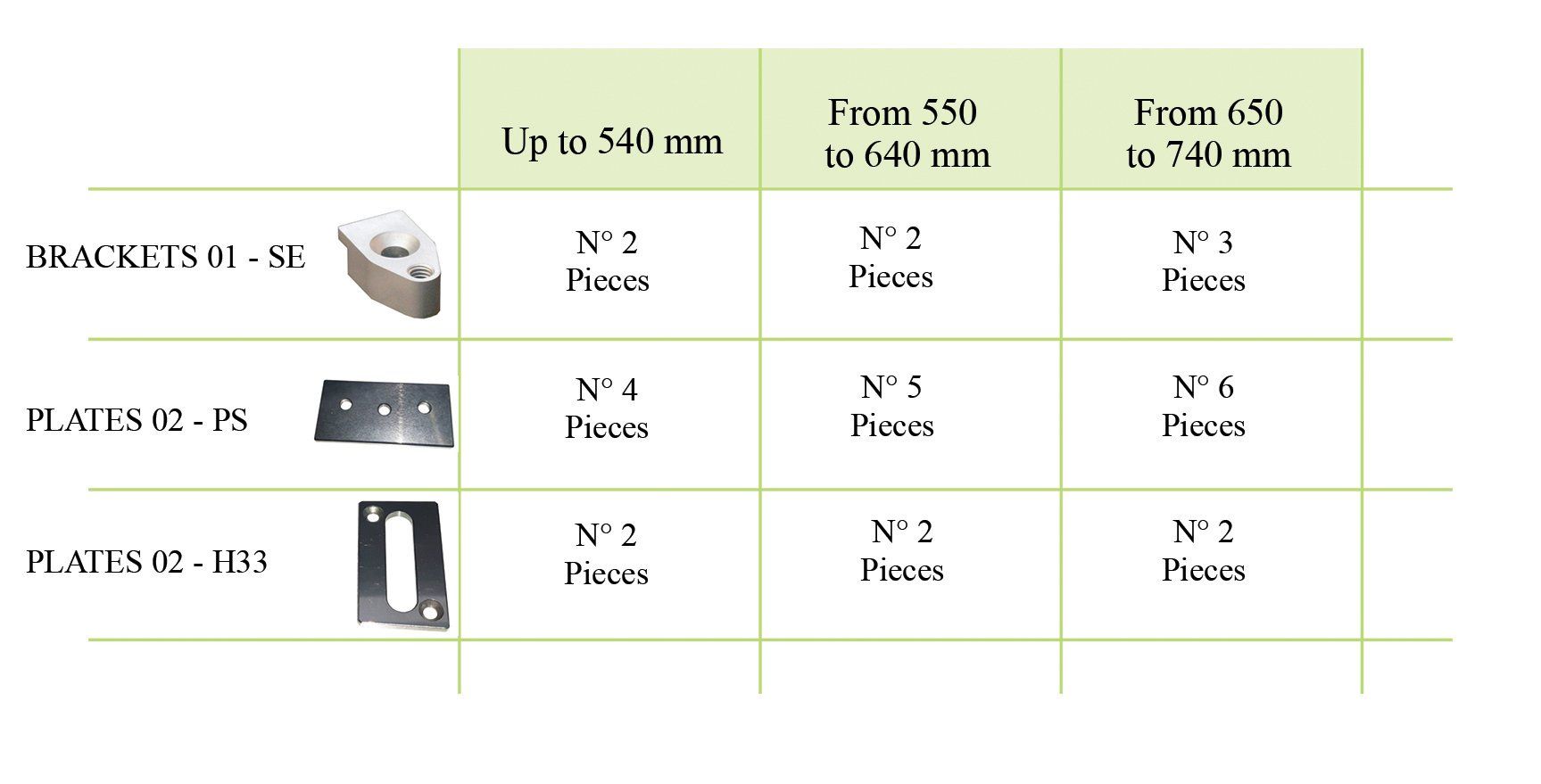

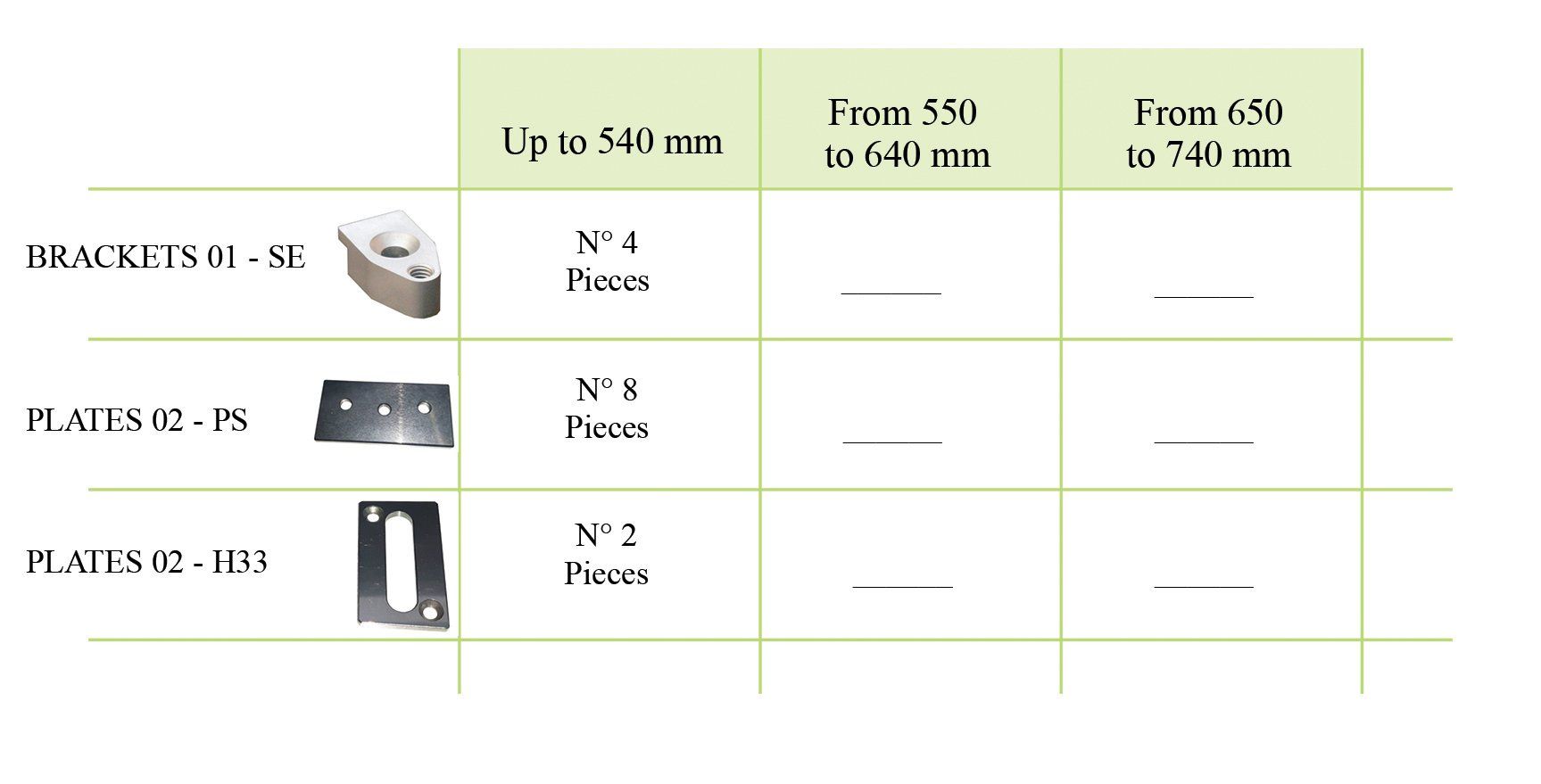

ACCESSORIES IN ACCORDING TO THE DISTANCE BETWEEN HOLES OF THE MACHINE TABLE

02 - TBB

BASIC CROSSBAR BILATERAL

From CHF 2.366,00

Crossbars with 43 mm span adjustment.

Can be used on both sides.

The piece is fixed using the brackets 01 - SE.

For work with the work piece

placed at the same height as the machine table

For work with the work piece

placed at 3.3 mm from the table of the machine insert the spacer 02 - H33

ACCESSORIES IN ACCORDING TO THE DISTANCE BETWEEN HOLES OF THE MACHINE TABLE