PLUS CROSSBAR

PLUS CROSSBAR

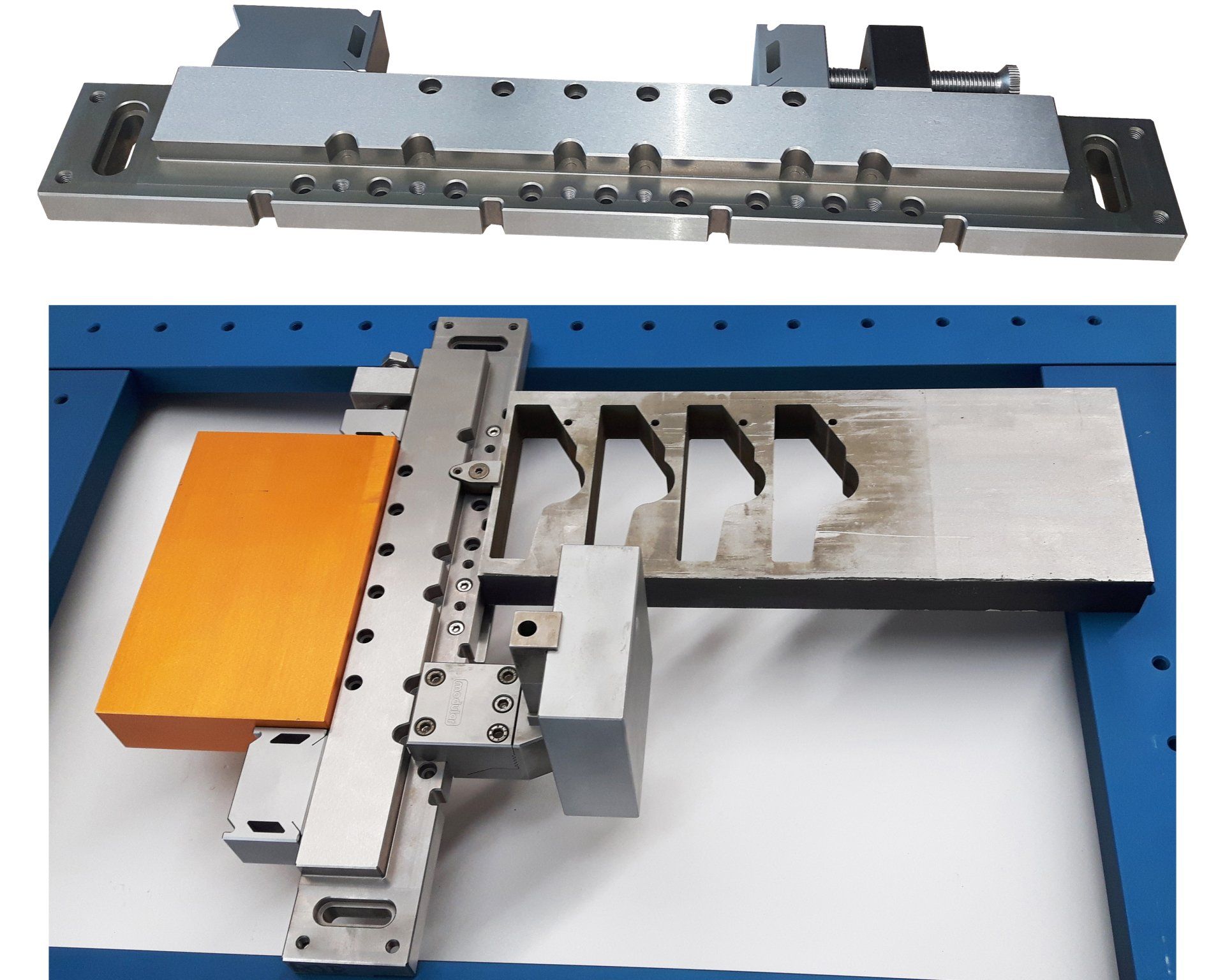

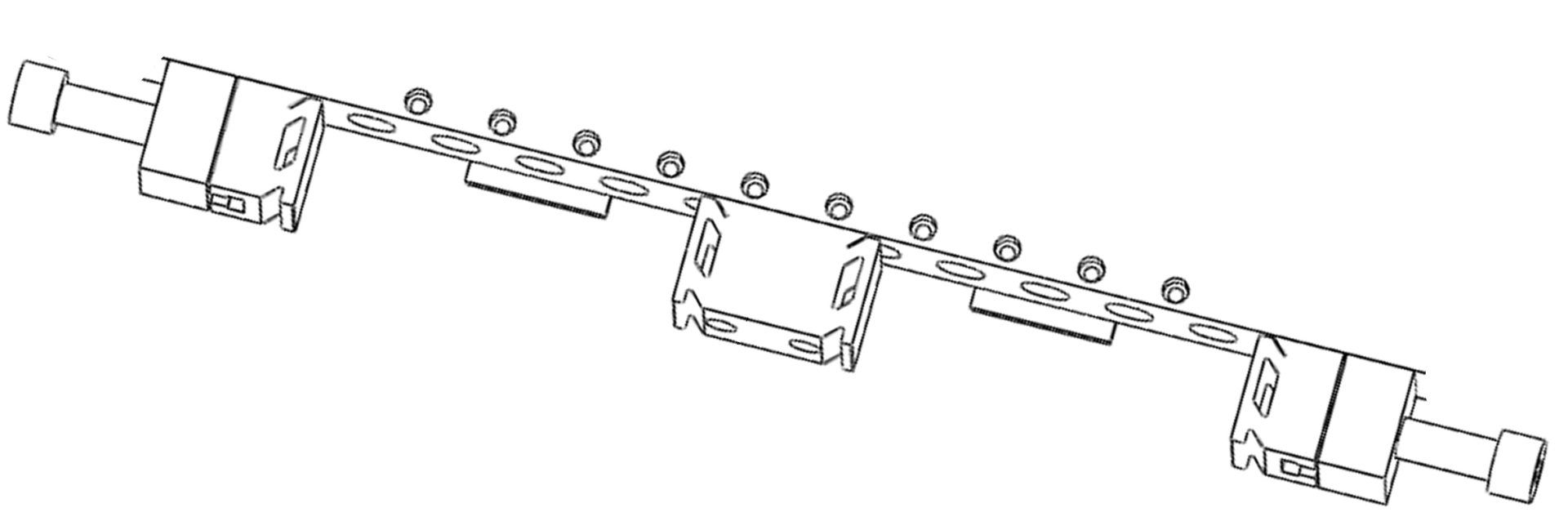

Crossbars with fixing slot made according to the distance between holes of each machine table.

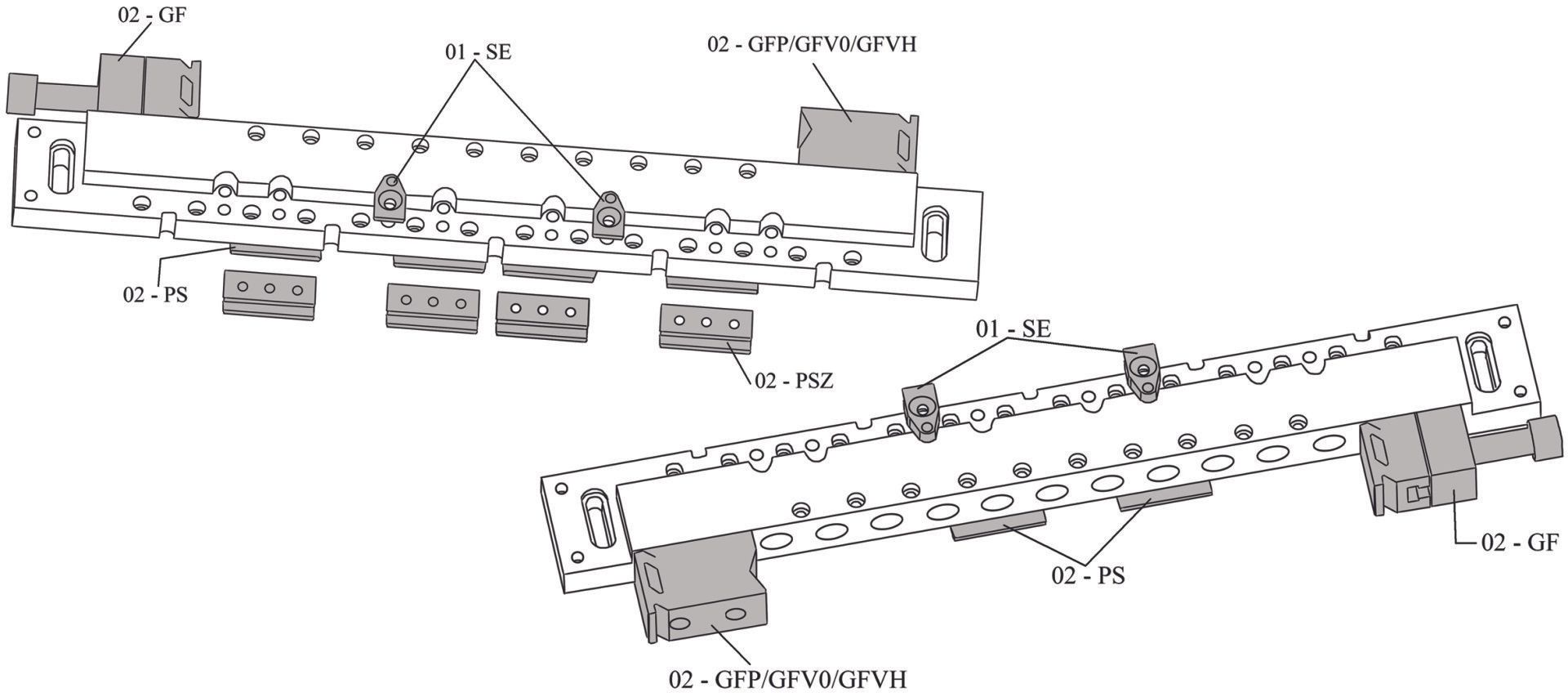

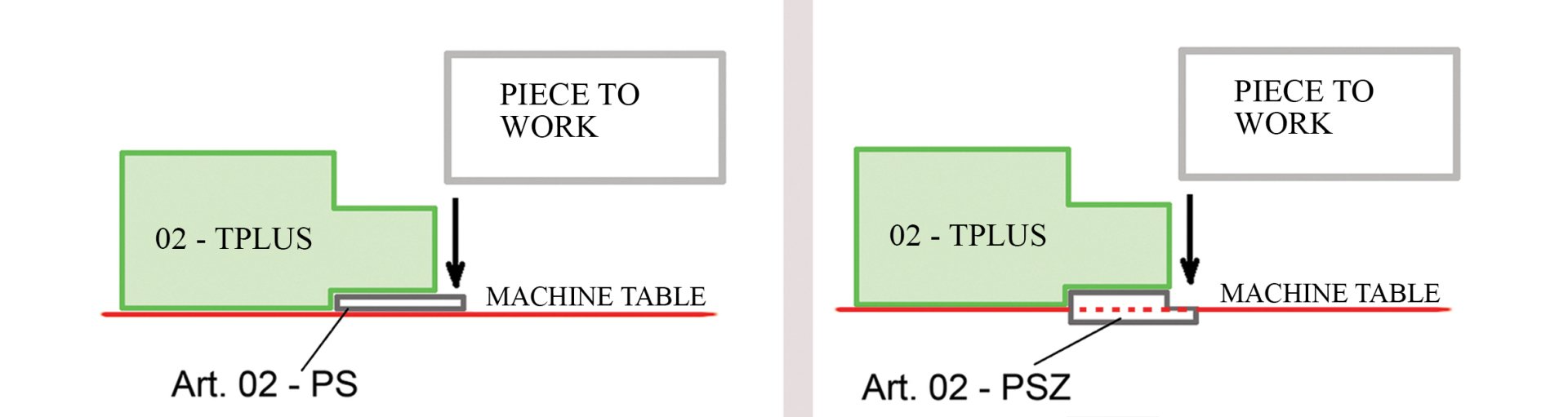

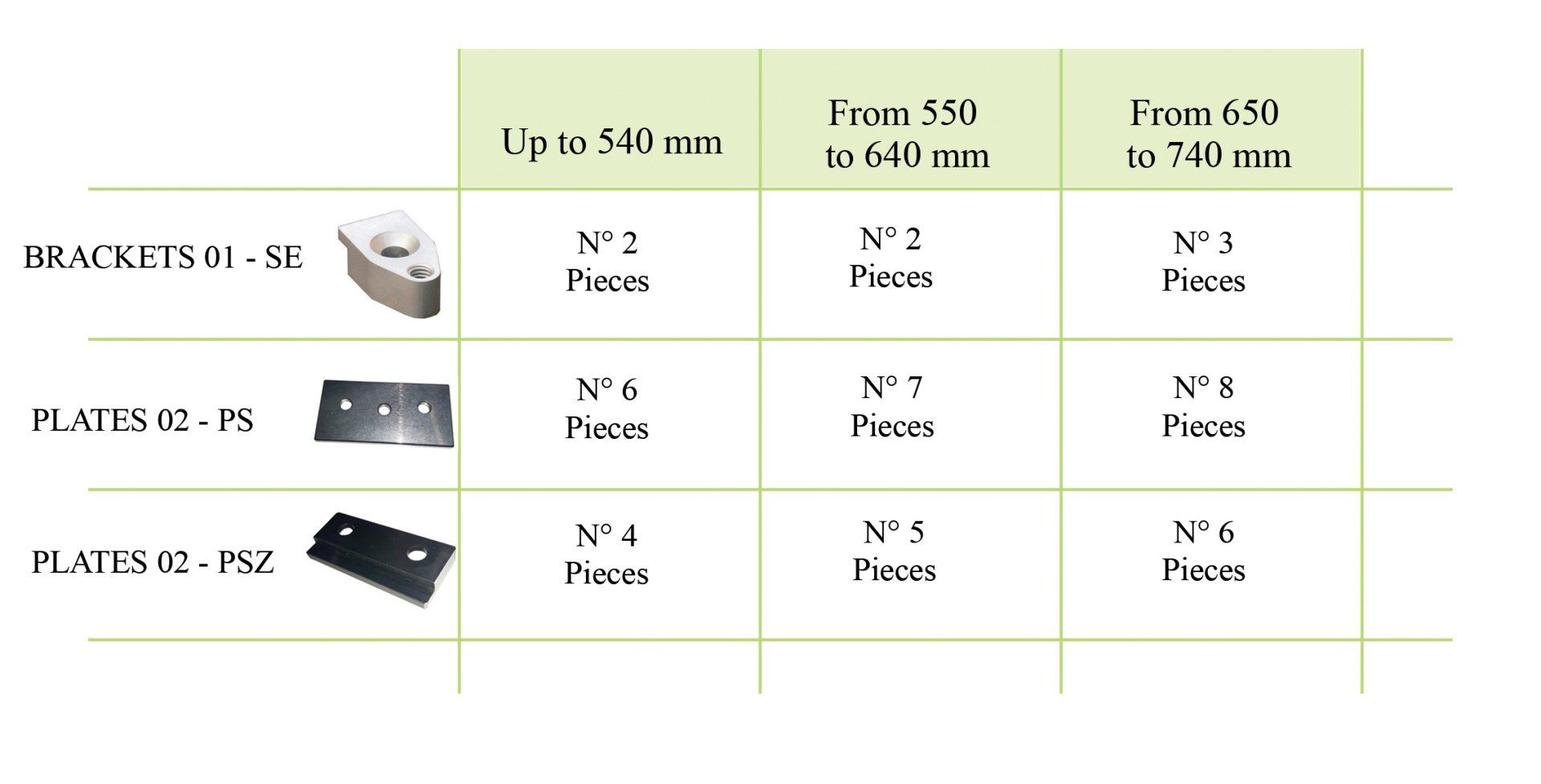

Each crossbar is equipped with fixing brackets Art. 01 - SE, and a series of workpiece holder plates Art. 02 - PS to be used for placing the workpiece at 3. 3 mm above the machine table. Or from a series of workpiece holder plates Art. 02 - PSZ to be used to place the piece to be machined at zero with respect to the machine table.

Possibility of anchoring all clamp - body, LINE 01 and ESSENTIAL LINE

02 - TPLUS

PLUS CROSSBAR BILATERALE

From CHF 2.599,00

(excluding fastening set)

Crossbars with 25 mm span adjustment.

On the opposite bank one can find a maxi clamp useful for fixing large pieces composed of one or more fastening set and two support plates Art. 02 - PS designed to facilitate the clamping of the pieces. They must be removed before processing begins.

The fixing of the piece takes place through adjustable clamp bodies LINE 01, the brackets 01 - SE, or by means of the fastening set.

For work with the work piece

placed at 3.3 mm from the table of the machine

insert the plates 02 - PS

For work with the work piece

placed at the same height as the machine table

use the plates 02 - PSZ

ACCESSORIES IN ACCORDING TO THE DISTANCE BETWEEN HOLES OF THE MACHINE TABLE

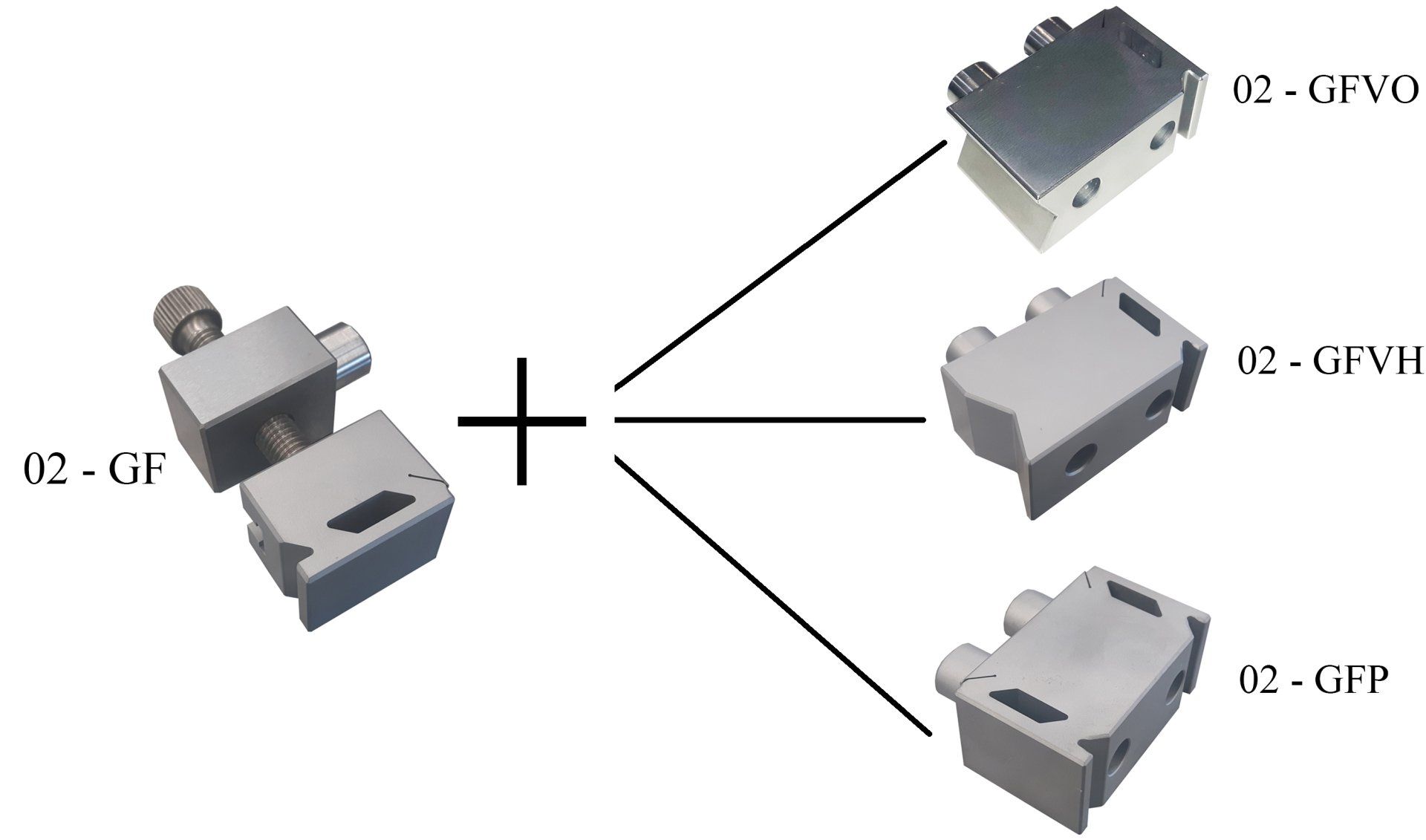

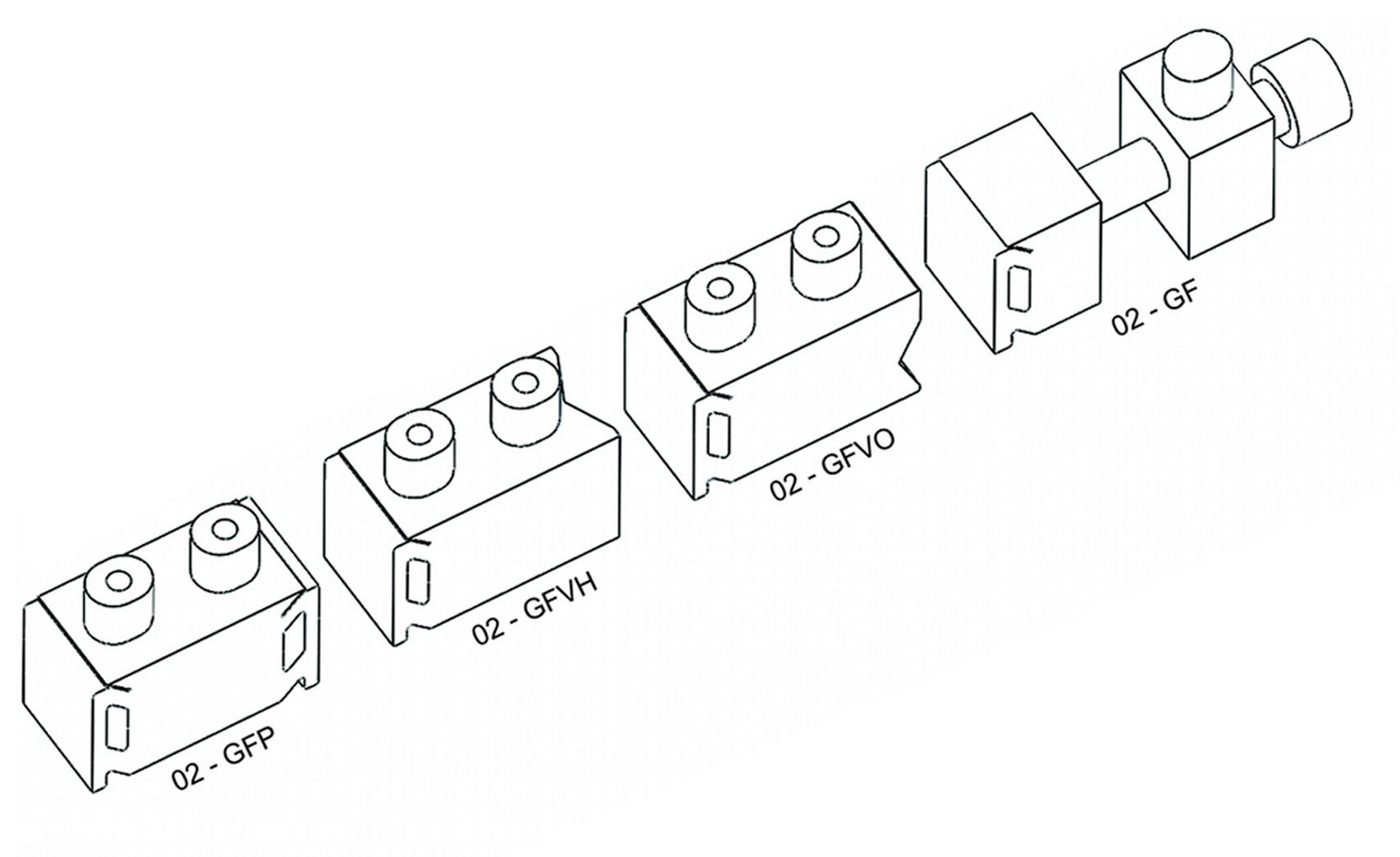

The Fastening set consists of a mobile part, Art. 02 - GF and a fixed part which can be of three versions.

The chosen fastening set is not an integral part of the Traverse, which must therefore be ordered separately.